The fist successful student project at HyLeC

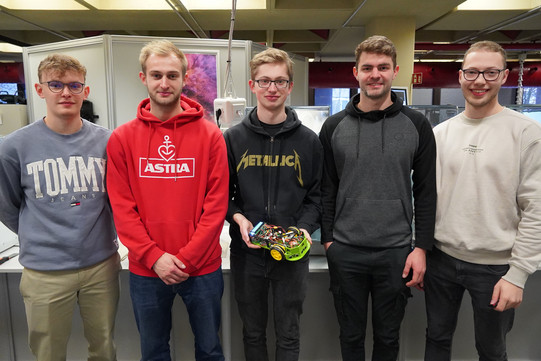

Julian T., Jean-Pierre B., Julian L., Moritz B. and Jonas P. used the 3D printers during free opening hours over several days and weeks for their student project. For their mechanical engineering studies, they built a model car that can be controlled by remote control as part of their Introduction to Programming 2 course.

In the process, they also entered into an exchange with other students on site. They contributed their own experiences and considerations and thus enriched the whole HyLeC.

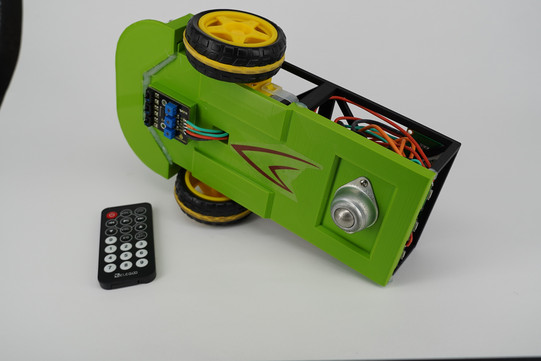

They discussed the designs they handed over to the 3D printers with the employees on site. It became very clear that not only the grade for the test is important for them, but also the process and much more important: sustainable work. One design was even completely changed in order to waste less material and still achieve the same stability in the model.

The somewhat hesitant statement "it's not beautiful" was not entirely comprehensible when the five proudly presented their result. In the eyes of the HyLeC team it really has a lot of character and charm. The fact that a soldering accident at the front gave the car a dent only makes it even more charming.

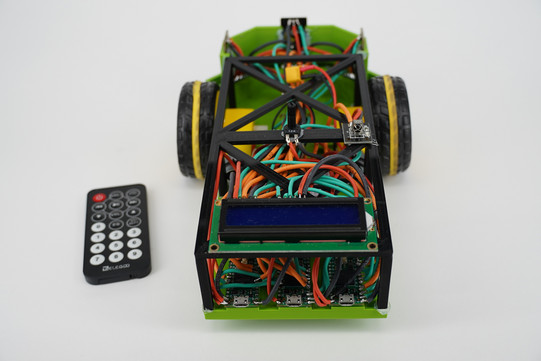

The car can find its way in two ways: Either it follows a pre-taped line or light reflections with the sensors on the bottom of the car, or alternatively it detects obstacles with the cameras mounted on the front. As long as it doesn't detect any obstacles, it moves forward, otherwise it changes direction. The fabulous design with the ball bearing at the back is unbeatable in the eyes of the HyLeC team. Now the three are eagerly awaiting their grade. From HyLeC's point of view, clearly a 1+!

Videos vom Auto in Aktion

Please confirm video activation.

After activation, cookies will be set and data is sent to YouTube (Google).

To the Google Privacy Policy

Please confirm video activation.

After activation, cookies will be set and data is sent to YouTube (Google).

To the Google Privacy Policy